Balancing

On rotating components, unbalanced loads are often the cause of vibrations that can impair the smooth running of the system, with potentially catastrophic effects.

Acoustic noise, induced stresses in support elements (bearings, etc.), premature damage, the consequences of these vibrations can sometimes go beyond the moving system and lead to the destruction of the installation.

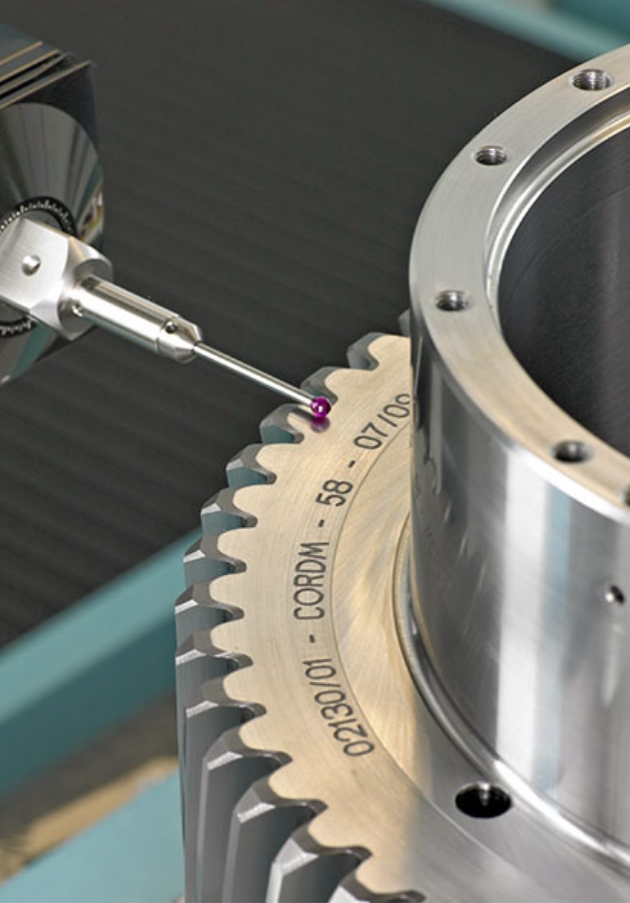

Whether static or dynamic, we can balance individual parts or sub-assemblies to an accuracy of 2.5 g.mm in-house (finer accuracies are sub-contracted to qualified partners).

In this way, CORDM can guarantee you the best operation for your gears and shaft lines.