Our workshop

Since it was founded in 1982, CORDM has developed one of the most modern and efficient production facilities for the manufacture of gears, thanks to a strong investment policy.

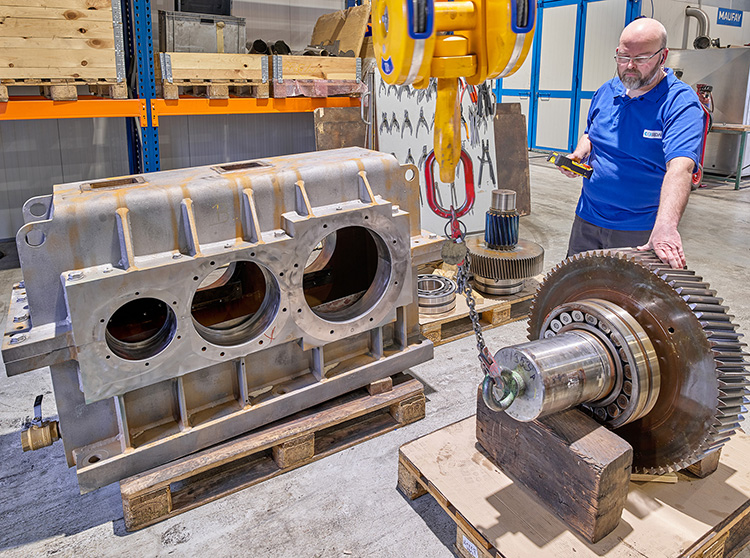

Today, we have a covered production area of 7,000 m², and around fifty latest-generation machines at your disposal, so that you can benefit from the most precise technologies dedicated to the manufacture of your gears.

A team of 50 experienced, fully-trained, autonomous and versatile technicians are at the controls of our production tools, ensuring that we can respond quickly and adapt to any situation.

The diversity of our machines and the fact that the workshop operates in 3×8 shifts means that we are autonomous in terms of machining and can work more flexibly. Any heat treatments included in our offers are subcontracted to selected, reliable partners, qualified by our quality department to provide you with a global manufacturing solution.

Moreover, our fully-equipped assembly workshop enables us to offer you fully or partially assembled assemblies to suit your needs. This means that you receive a component in your workshop, ready to be integrated into your systems.

Gears manufacturing

Gear cutting

Teeth grinding

Balancing

Gearboxes repair

Gear production: precision as a core requirement at every stage

At CORDM, gear production is far more than a sequence of technical operations, it is a complete engineering process where every step, from gear manufacturing to gear repair, is driven by a single priority: precision.

In the demanding world of mechanical power transmission, the quality of a gear determines the reliability of an entire system. Our mission is to ensure that reliability, whatever the constraints or configuration.

Custom gear manufacturing: the foundation of performance

Gear manufacturing is the cornerstone of any well-designed transmission system. It begins with carefully selected raw materials, and continues through a series of quality controls and adjustments that guarantee perfect alignment with our clients’ functional requirements. With years of expertise, we produce custom-made gears tailored to the most specific industrial environments. Each component is designed to last, to operate flawlessly, and to integrate smoothly into a mechanical assembly.

Gear cutting: ensuring geometric accuracy

Gear cutting is a central stage in the production process. It defines the tooth profile and ensures the gear’s ability to transmit motion efficiently. At CORDM, we rely on state-of-the-art gear cutting machines to deliver impeccable regularity, even in series production. This precision minimizes backlash, reduces friction, and ensures controlled wear over time.

Gear grinding: achieving high-precision finishing

Following gear cutting, gear grinding provides the finishing touch. This operation achieves extremely tight tolerances, with micron-level precision. It is essential for high-performance applications that demand low noise levels, smooth rotation, and enhanced longevity. Our advanced gear grinding equipment guarantees perfect surface finishes and precise geometry across every tooth.

Gear balancing: reducing vibrations and securing performance

Gear balancing is crucial, especially for components operating at high rotational speeds. An unbalanced gear can create vibrations, cause premature wear, or reduce the overall efficiency of a system.

That’s why this stage is systematically integrated into our production process. Through dynamic balancing, we ensure quiet, stable, and secure operation.

Gear repair: extending the life of your components

A worn or damaged gear is not always beyond repair. Our gear repair service extends the lifespan of your components while maintaining their original performance. We analyze each mechanical gear, identify wear causes, and restore the tooth geometry, correct defects, and rebalance the assembly when necessary. This approach is not only cost-effective, but also sustainable, helping reduce waste and extend the value of your industrial equipment.

Comprehensive expertise in gear production

Every stage of our process, from gear manufacturing and gear cutting to gear repair, is carried out by specialists using state-of-the-art equipment and driven by a constant commitment to quality.

On our website, you’ll find dedicated pages for each of these services, offering deeper insight into our methods and expertise. At CORDM, we believe that a high-quality gear is born from meticulous attention to detail at every moment. It is this level of precision and discipline that truly sets us apart.