Gear calculation: a critical step to ensure reliability during commissioning

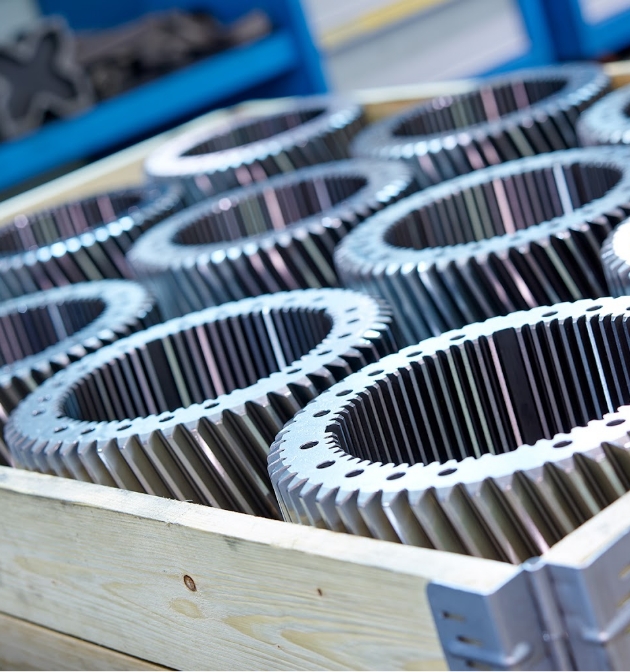

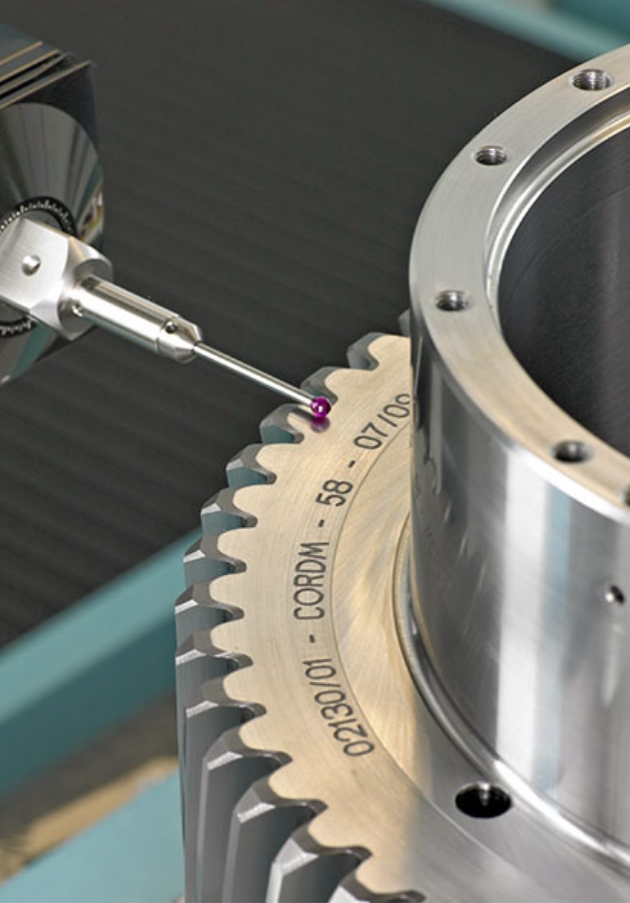

At CORDM, gear calculation is never a theoretical exercise. It is an essential phase within our custom gear manufacturing workflow to guarantee robust, durable, and application-ready mechanical gears. Before every production run, our engineers validate or optimize the technical parameters of your gears to ensure reliable operation from the very first commissioning.

Using specialized engineering tools, we carry out the calculation of spur gears, the calculation of helical gears, and the calculation of bevel gears according to your requirements. Our goal is to verify gear geometry, load capacity, expected service life, tooth stress, and lubrication conditions, all while respecting your technical specifications.

Each pinion calculation or planetary gear calculation we perform strengthens the reliability of the future manufacturing process. For complex projects or specific constraints (variable loads, abrasive environments, thermal stresses), we implement targeted technical adjustments to improve mechanical strength or overall efficiency.”

We do not simply deliver a gear calculation report, we deliver a fully compliant, machined, tested, and ready-to-operate component. This is the strength of our integrated approach: combining engineering expertise, production workshops, and field-proven know-how. At CORDM, gear calculation is a genuine industrial decision-making tool. It allows you to go beyond simple replacement by ensuring compatibility, reliability, and long-term performance for every mechanical gear produced.

Thanks to this comprehensive methodology, each gear calculation we perform becomes a guarantee of performance for your installation. You benefit from precise dimensioning, impeccable manufacturing quality, and flawless commissioning. This is the standard of excellence that drives us every day to support the most demanding industrial sectors.