Grinding

Cylindrical and surface grinding:

Our production capacities are as follows:

Horizontal cylindrical grinding: for gears up to 1.5 tonnes – Ø 600 x 2500

Vertical cylindrical grinding: for gears up to 2 tonnes – Ø 1600 x 600

Surface grinding: Length 1500 x Width 500 x Height 400.

We can work on single parts or mass-produced parts.

Please do not hesitate to contact us or send us your drawings directly for a quotation.

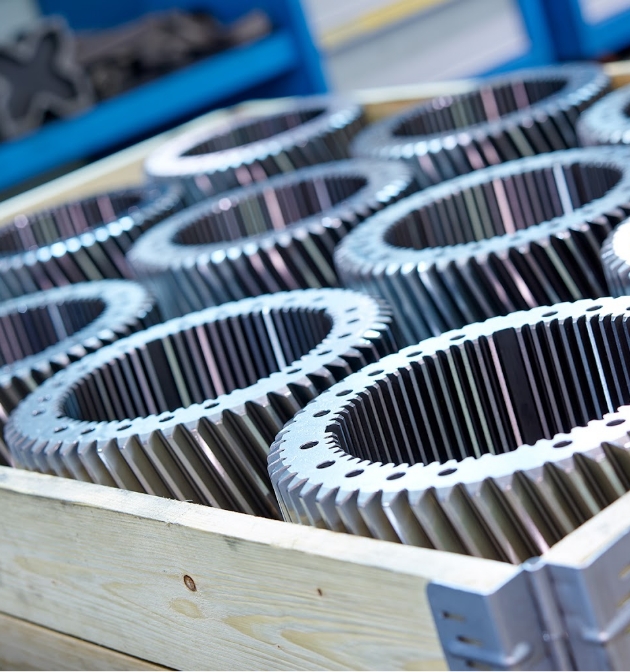

External gear grinding:

We can grind gears up to 1600 mm in diameter to ISO 1328 quality 4. To do this, we have large-scale CNC grinding machines using a grinding wheel process designed to grind very high-precision gears. Our production facilities enable us to achieve extremely precise surface qualities.