Custom mechanical gearbox design: CORDM’s solution for demanding industrial applications

In industrial environments, every setting comes with its own challenges. Confined spaces, extreme temperatures, fluctuating loads, humidity, or dust: conditions that very few standard gearboxes can withstand over time. This is why at CORDM, each mechanical gearbox is engineered as a custom solution, designed to suit your real operating conditions.

A mechanical gear reducer is not a generic component. It is the core of the power transmission system, ensuring optimal torque conversion and reliable motion control. When properly engineered, it reduces speed, increases torque, and protects the entire kinematic chain. Every gear reducer we manufacture is precisely sized to meet your load requirements, duty cycles, and integration constraints, whether for a special-purpose machine or a production-series system.

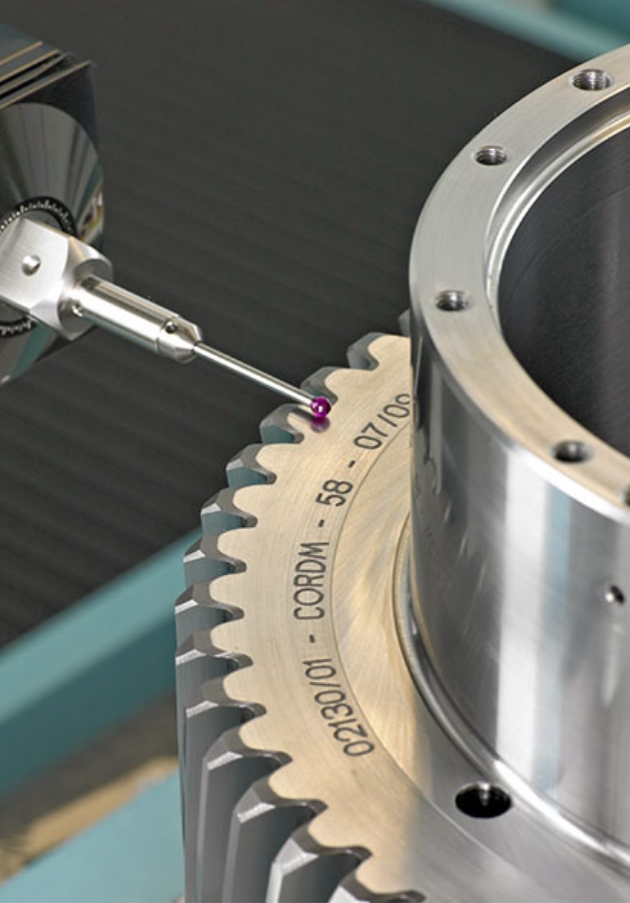

Our expertise covers the full process: from load calculation and gearbox sizing, to defining the right type of mechanical reducer, selecting materials, and performing the appropriate heat treatment on critical components. Thanks to our in-house design office, we deliver mechanical speed reducers perfectly tailored to your needs: parallel-shaft gearboxes, planetary gear systems, bevel gear reducers, or combined configurations. The goal is always the same: reliability, compactness, and performance.

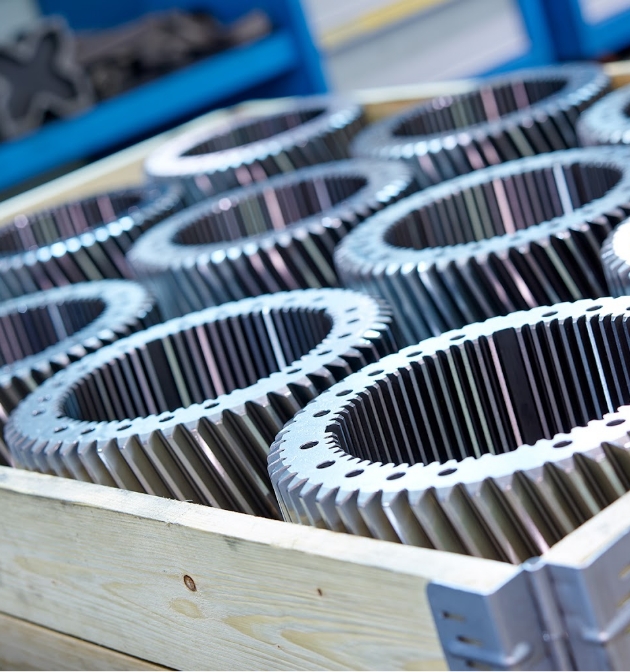

Our ability to manufacture all mechanical gearbox components in-house : shafts, housings, gears… gives us exceptional flexibility.. We can precisely adjust gear ratios, tooth profiles, and reducer geometry to meet your technical specifications. This mastery guarantees quiet operation, extended component life, and improved energy efficiency.

At CORDM, producing a gearbox reducer is more than machining parts: it is a matter of expertise, engineering insight, and a commitment to delivering the most suitable solution. For every machine, every environment, and every application, there is a mechanical reducer perfectly dimensioned, and we design it with you.