The origin of the company RDM (name of the founder René De Malzine) started at the beginning of the last century when the company was based on the Belgian territory.

During the First World War, the factory was transferred in the area of Paris (COLOMBES) for security reasons, and then moved to VERDUN (Meuse) …

Thanks to our working procedures and our numerous quality certificates, we engage ourselves and assure a complete traceability of our products and professionalism at all time.

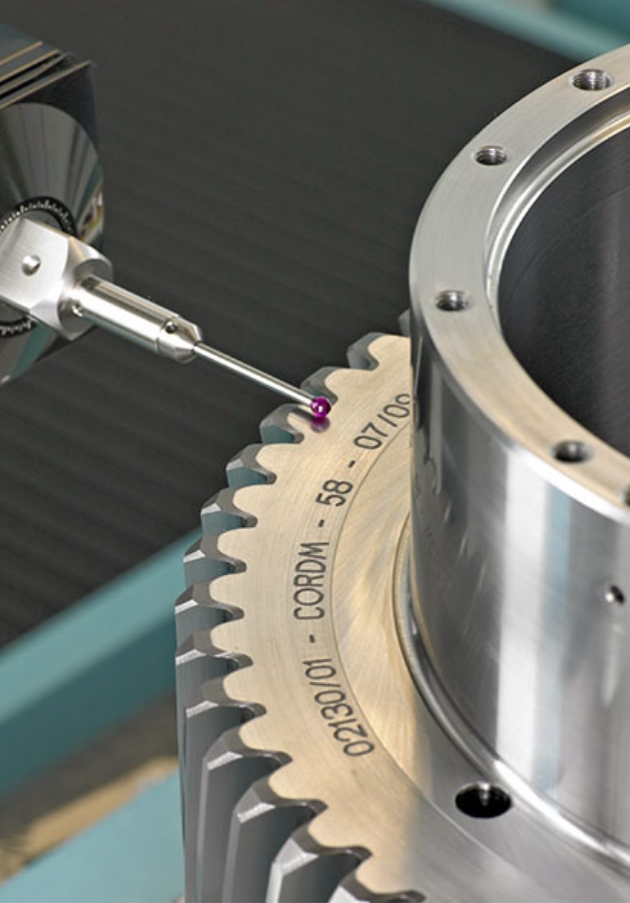

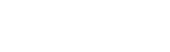

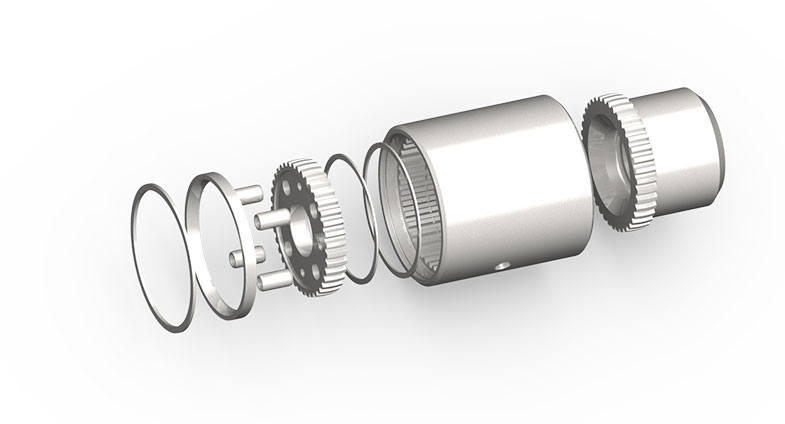

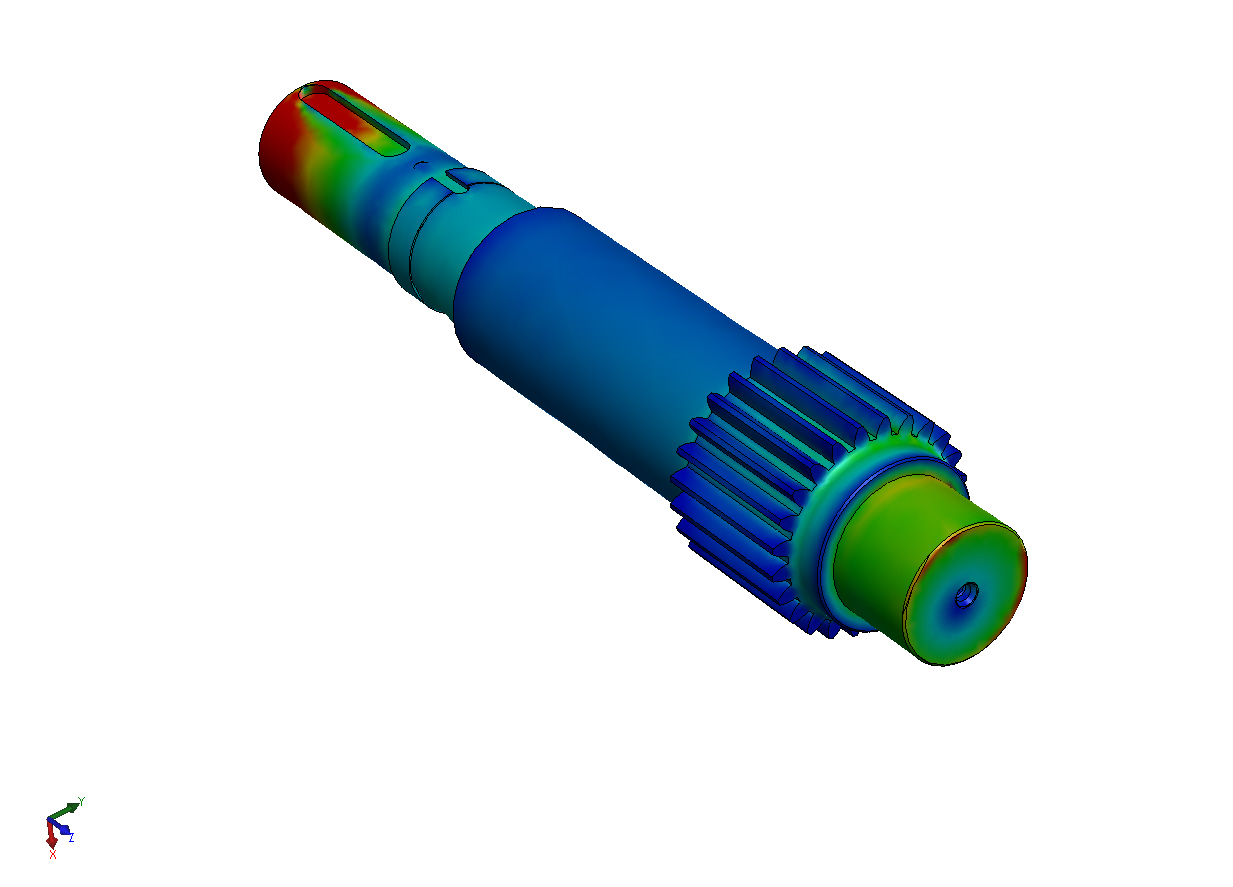

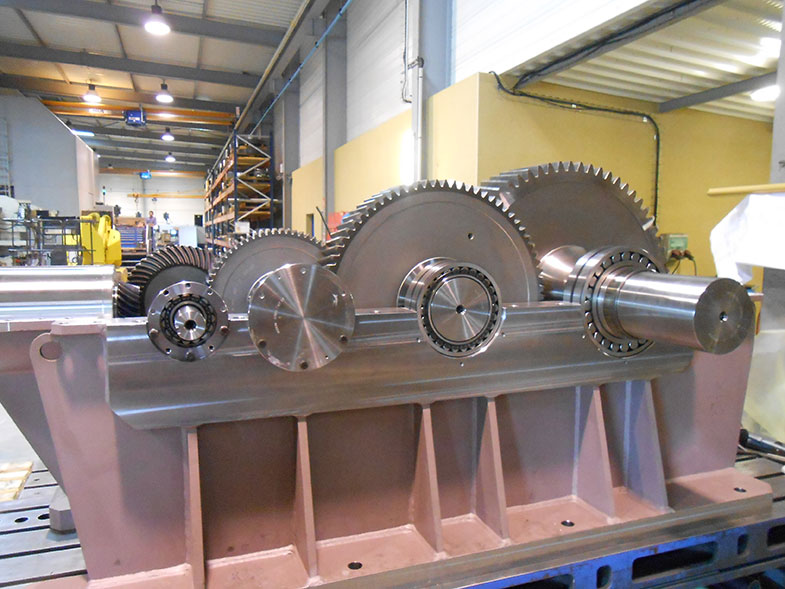

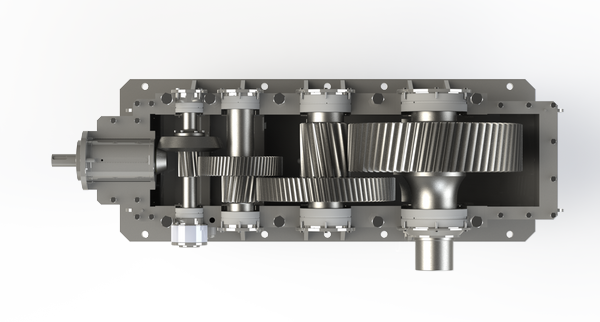

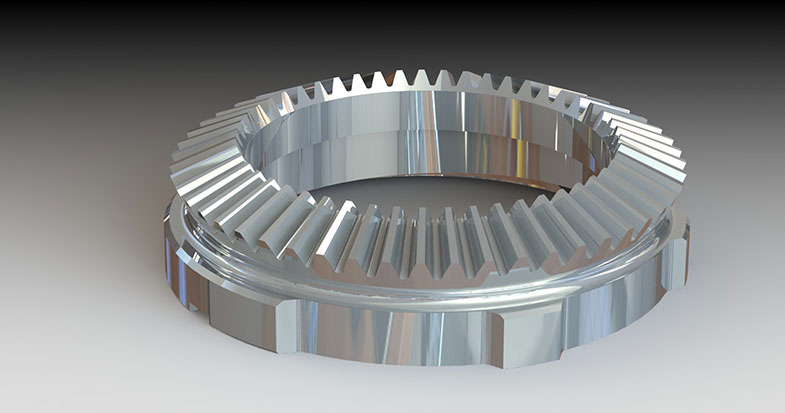

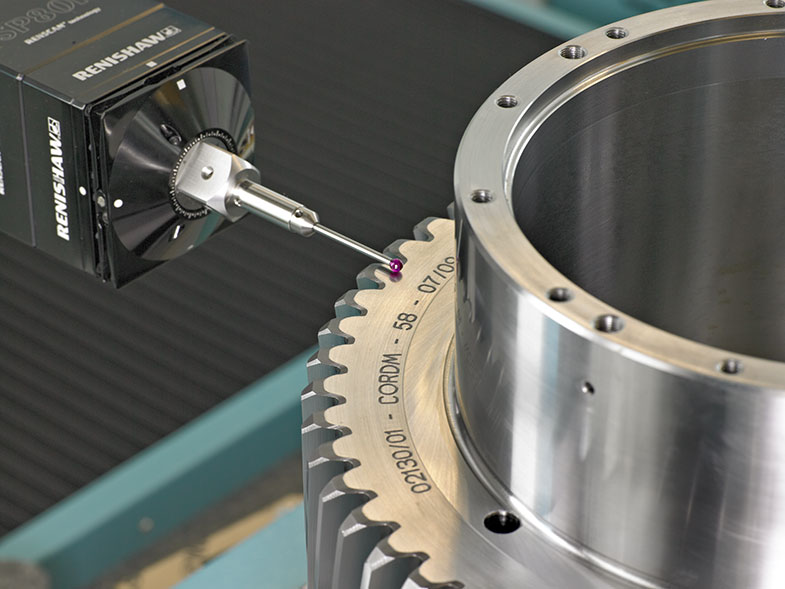

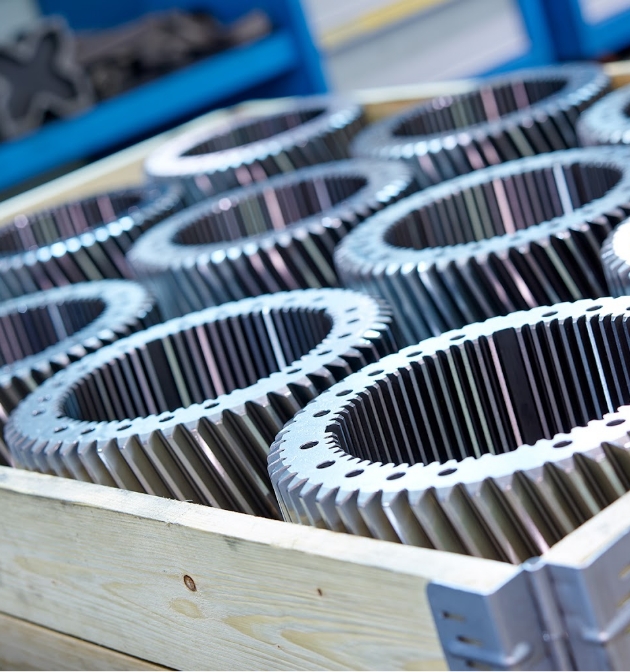

Since 1982, Cordm, your gear manufacturer, has been your partner for all your industrial mechanical transmission projects: the design and manufacturing of precision gears, mechanical reducers, drive shafts, and gear trains. Thanks to a fully equipped, innovative equipment, regularly reinforced by new investments, and unrivalled experience and know-how in machining, gear cutting, and repair, Cordm is able to supply all types of mechanical gears and gear teeth (helical, spur, etc.), according to your gear models and in strict compliance with your specifications: bevel, planetary, helical or rack and pinion gears, for example. For all your business sectors (rail transport, marine, crushing and mining or energy), Cordm offers a complete range of services for mechanical gears and pinions: design, milling, gear grinding, maintenance, and even balancing of drive shafts. Throughout the lifespan of your equipment (gear reducers, rack and pinion gears, etc.), our specialists provide expert guidance and personalized support. For every project, Cordm delivers expert solutions that fully meet your requirements, while also providing technical added value. With customer satisfaction at the core of our business, every product we deliver—whether an epicyclic gear train, splined shaft, or planetary reducer—is backed by a strict quality policy.

Alongside our expertise in gear design, grinding, and cutting, both for gears and speed reducers, our skills in precision industrial mechanics allow us to handle complex part orders and offer a complete range of mechanical transmission components: racks, gear wheels, pinions, and transmission chains. Beyond standard parts, our experts are attentive to every client request and can produce customized parts, from chain or bevel pinions to simple or planetary gear trains, including speed multipliers. No matter the type or size of the gear, rack, pinion, or wheel you need, our team puts its expertise at your service, developing unique solutions in line with the most demanding quality standards. Our mechanical gears are used across a wide range of industries, including rail transport (high-speed trains, freight), energy (wind, oil, nuclear), steel (paper mills, cement plants, steelworks), infrastructure, mining and crushing, lifting equipment, and marine (direct propeller drive). We use high-quality materials in the manufacture of our gears to guarantee high quality and smooth operation of your precision gears.

For all your precision gear projects, trust Cordm.