Gears manufacturing

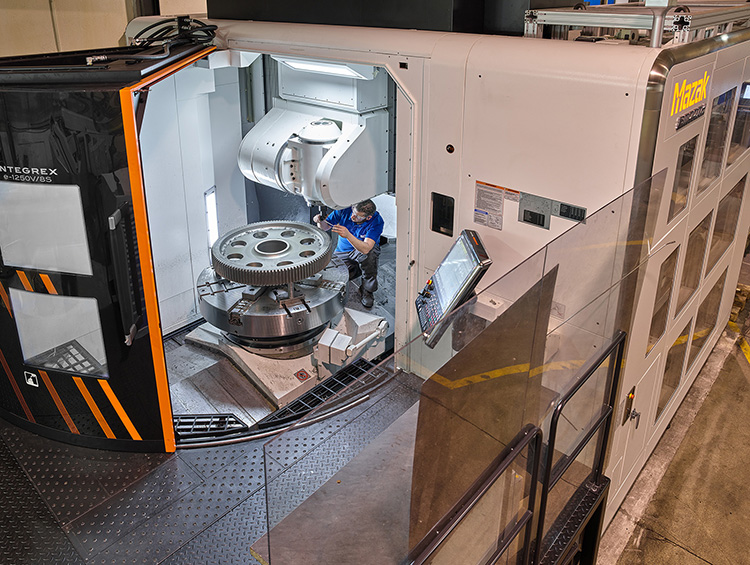

Our core business is the manufacture of all types of high precision gears up to 1600 mm diameter module 40 – Quality 8 ISO 1328 after hobbing up to quality 4 ISO 1328 after teeth grinding.

We offer the production of pinions and cylindrical gears with spur, helical, bevel, spiral, internal toothing, racks, toothed cracks, spline shafts, pinions and chain wheels, and many others for different types of rack and pinion transmissions; cylindrical gears with external contact, cylindrical gears with internal contact, pinion/bevel gears.

Our gears are manufactured from standard steels (open-die forging, close-die forging, laminated bars, forged and rolled bars) according to the specifications of our customers.

We also offer heat treatment of gears in the mass, nitriding, induction hardening, surface hardening, induction or case hardening and tempering. Other surface treatments can be offered.

Please do not hesitate to contact us.

Our sales teams stay at your disposal.

Gear manufacturing: expertise and mechanical precision

At CORDM, we design and manufacture custom power transmission solutions tailored to your technical constraints. As a gear manufacturer, our approach is unique: we start by listening to your needs, analyzing your mechanical environment, and delivering precision-engineered gears built to the highest standards. Every project is different, and that’s exactly what drives us.

Custom gear manufacturing always begins with a deep understanding phase. We work closely with you to identify key constraints: transmitted loads, operating environment, required precision, thermal and dynamic conditions. It’s not just about dimensions and gear tooth profiles, it’s about performance goals. Whether it’s a custom pinion for a reduction system or a bevel gear integrated into a complex assembly, our mission is to deliver the most suitable solution.

Our team of specialized engineers and gear technicians collaborates with yours to translate functional needs into high-performance mechanical components. Whether starting from an existing drawing or supporting you from the design stage, we bring technical support that makes CORDM a trusted gear supplier across multiple industries, from special machinery and heavy industry to automation and transportation.

Once all parameters are validated, we move into the gear cutting phase. Our France-based workshops are equipped to manufacture all types of gear teeth: spur, helical, bevel, worm gears, and racks. We also produce small to medium gear series, always with micron-level precision. Every operation, from gear hobbing to grinding, including heat and surface treatments, undergoes strict inspection to ensure reliability and durability.

Being a pinion manufacturer means more than fulfilling a technical brief. It’s about anticipating, advising, and refining every detail based on your constraints. We go beyond manufacturing : our rigorous quality control, functional tests, and adaptable processes guarantee reliable, high-performance, and long-lasting gears, whatever the application environment.CORDM stands for technical precision and close customer collaboration. Our clients don’t just seek machining, they come for expertise, dialogue, and durable, tailored solutions. If you’re looking for a custom gear manufacturer or a reliable partner in gear production, we’re ready to support your next project.